Well I decided not to jump ship and went back to work on the elevators.... The first elevator is complete, and this elevator is the one with the trim tab so its more complicated. Again I cut, match drilled, deburred, dimpled, and primed the reinforcements.

Heres the viking boat you build for counterweight.

Riveting on the reinforcements with the rivet tape I finally purchased.

The inside as the reinforcements are riveted...

All installed!

Putting the skeleton together for match drilling....

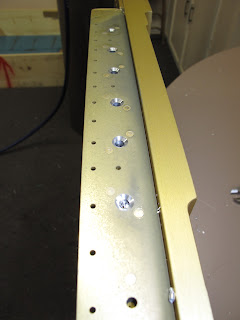

Next I needed to make the panel for the trim cable access. Here is the reinforcement plate that gets attached to the skin. I first match drilled it to the skin, and then dimpled the skin and the plate. You can see the dimples here.

Next I dimpled the inside holes, deburred them, and began attaching plate nuts. These were kinda a pain to install just because of getting access to the back of the rivet with the rivet set.

And the dreadful folding.... Heres my wood block inside.

Markings for proper location

The top block.

And my decently acceptable, but honestly bothers me, folded edge.

Deburred and primed, now its time to rivet!

The horn getting attached to the skeleton.

Next I attached the trim cable access plate assembly.

And finally riveted the skeleton in! With the help of some friends, we got the leading edges rolled and attached. It was actually really difficult due to the strength of the skin. It also means that we were trying to just get it done and didn't get any photos of the process.